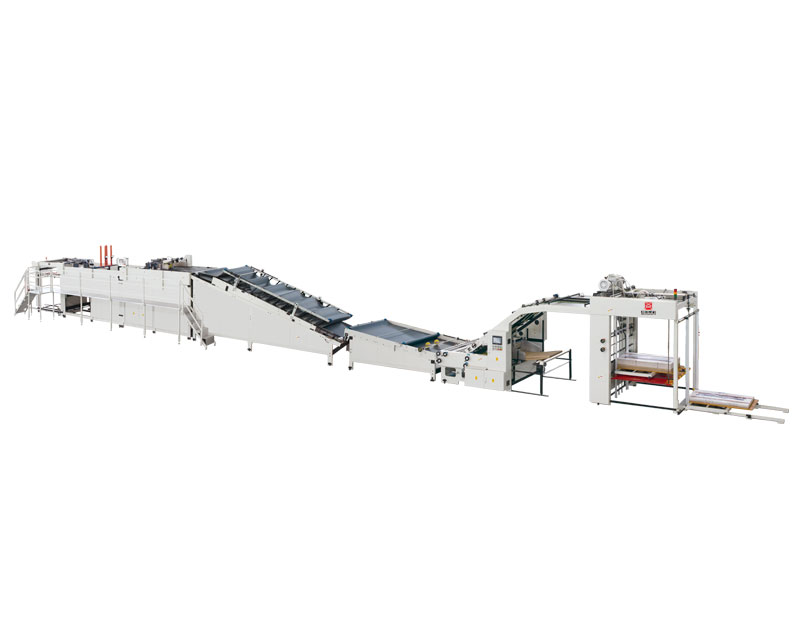

Paper laminating machine series

FUNCTION CHARACTERISTIC

1. All the key steel parts like steel wall plates camshaft are high

grade steel ones and machined in CNC center with high precision to

ensure the stability.

2. High speed operation parts like shafts rollers are high grade steel

ones and after thermal refining and dynamic balance processing to make

the sure the stability when running in high speed in the long run.

3. Motor Conveyors chains bearings and so on are famous brand in domestic and overseas to ensure the stability in the long run.

4. Electric parts are from international brand such as Omron Schneider IDEC and so on.

5. ISO9001 quality system has executed thoroughly. Incoming quality

control part testing installation processes inspection whole machine

testing are all strictly controlled.

TECHNICAL SPECIFICATION

YC146

| Model | YC146 | |

| Max. Sheet Size(mm) | 1450x1450 | |

| Min. Sheet Size(mm) | 500x450 | |

| Thickness of Surface Paper(g/m2) | 180-800 | |

| Appropriate Paper(mm) | A、B、C、D、E、Fcorrugated paper,thickness≤10 | |

| Max. Speed(s/h) |

10000sheets/hour, 160m/min |

|

| Laminating Precision(mm) | ±1.5 | |

| Power(kw) | 27 | |

| Weight(kg) | 15600 | |

| L×W×H (pedal not included)(m) | 28×3.3×2.85 | |

YC166

| Model | YC166 | |

| Max. Sheet Size(mm) | 1650x1650 | |

| Min. Sheet Size(mm) | 500x500 | |

| Thickness of Surface Paper(g/m2) | 180-800 | |

| Appropriate Paper(mm) | A、B、C、D、E、Fcorrugated paper,thickness≤10 | |

| Max. Speed(s/h) |

10000sheets/hour, 160m/min |

|

| Laminating Precision(mm) | ±1.5 | |

| Power(kw) | 27 | |

| Weight(kg) | 17300 | |

| L×W×H (pedal not included)(m) | 30×3.5×3 | |

冀公网安备 13022902000298号

冀公网安备 13022902000298号