FUNCTION CHARACTERISTIC

TECHNICAL SPECIFICATION

LOCAL DESCRIPTION

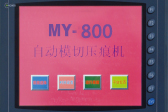

MY-800

| Model | MY800 |

| Max. Paper Size(mm) | 800×620 |

| Max. Die-cutting Size(mm) | 790×610 |

| Min. Paper Size(mm) | 350×260 |

| Max. Die-cutting Speed(s/h) | 8000 |

| Sheet Thickness(mm) |

纸板0.1-1.5 瓦楞纸≤4 |

| Max. Pressure(T) | 200 |

| Total Power(KW) | 12.75 |

| Weight(T) | 9 |

| Dimensions(mm) | 4310×2100×1800 |

|

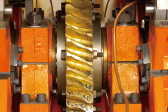

Main drive Worm gear material choice of quality wear-resistant alloy of copper made by precision machining fine scraping of senior technicians minimal wear and high precision. Crankshaft with chrome steel high-frequency quenching treatment long service life. The pendulum cast by the milling of cast iron high strength and wear. |

|

Feeder The feeder adopts the European technology with four suckers and five blowers. The suckers are adjustable to ensure the steady conveying of different type and shape of paper without stopping the machine. The easy to be adjusted functions can do thin and thick paper for an accurate convey. |

|

Paper Conveying Part The pressure of the paper conveying belt can easily be adjusted to ensure the constant conveying of paper to the desired position with little break down time. The paper conveying belts are imported and rubber pressers and the hair pressers are high wear-resisting. |

|

Paper Delivery Part Paper's delivery is automatic and orderly. Efficiency can be greatly increased as the vice delivery device in running time is adopted. Paper sheets to be cut can be checked anytime in running with the sampling mechanism. |

|

Feeding part The high speed motor stable feeding setting and 8 suction nozzles adapts in different width of papers. This kind of machine with auxiliary feeding part makes the feeing continuous. The feeding and delivery parts are made of Taiwan Sheng state deceleration motor and code paper settings make the machine more convenient and flexible to operate especially for the efficiency of corrugated paper production. |

|

Gripper Bars The gripper bar is made of hard aluminum alloy with its surface treated by anode oxidation. It is with high intensity,little weight and intertia. Sheet's transferring can be finished with great precision in high speed. |

|

Electric Control The machine is controlled by OMRON PLC. All the electric parts are either from Japan France Germany or Taiwan. The man machine interface provides accureate working states of the machine. |

|

Die cutting part The safety design of die cutting bed and the knife template makes move easily. The Rotary device makes the install and fix more convenient and quicker. Pneumatic lock device makes the bottom more firm and accurate as well as time-saving. |

|

Man-machine Interface The high-resolving power interface in machine can inspect working state of the machine and display all information. It is convenient and reliable for machine's adjusting and trouble-shooting. |

|

Worm

Material selection the German high-quality alloy steel precision machining manufacture of a special heat treatment process. High accuracy long life wear and tear. |

|

Worm

Casting alloy bronze with good anti-friction and anti-gluing ability. Precision machining fine scrapers made by the senior technician. High precision no noise wear and tear. |

|

Pneumatic Clutch Adopt imported pneumatic clutch long life and low noise braking stable. |