Die-cutting machine series

FUNCTION CHARACTERISTIC

TECHNICAL SPECIFICATION

LOCAL DESCRIPTION

BMY-1200/1500 is a special equipment applying to die-cutting of advanced colorful boxes and cartons. The machine combines several advantages over many other die-cutters both at home and abroad. Gripper bars with high intensity are applicable to all kinds of cardboard, paperboard and corrugated paper. Frontal, back and side registration mechanism ensures great precision of die-cutting. Other parts are adopted such as intermittent mechanism with high precision, air clutch, pneumatic locking mechanism, programmable controller and man-machine interface. The interface can display various digital information of machine such as working speed, amount of paper processed, total running time, etc. It is easy to eliminate troubles according to the display of trouble shooting. Transducer is adopted to control the main motor in achieving stepless speed variation. The machine has a lot of sensors and safety-ensuring devices to guarantee the safety of operator and the environment. Frontal and back pressure can be adjusted separately. It is convenient to stop the machine by handy. It can also realize die-cutting without clipper margin.

BMY-1200

| Model | BMY-1200 |

| Die-cutting Style | platen press |

| Max. Paper Size(mm) | 1200×780 |

| Min. Paper Size(mm) | 400×400 |

| Max. Die-cutting Size(mm) | 1190×770 |

| Max. Die-cutting Pressure(T) | 320 |

| Paper Processed(mm) | cardboard 1-9 |

| Max. Die-cutting Speed(s/h) | 4500 |

| Main Motor Power(Kw) | 11 |

| Total Power(Kw) | 17 |

| Weight(Kg) | 13 |

| Dimensions(mm) |

5000×4000×2500 3150×2250×2500 |

BMY-1450

| Model | BMY-1450 |

| Die-cutting Style | platen press |

| Max. Paper Size(mm) | 1450×1030 |

| Min. Paper Size(mm) | 550×550 |

| Max. Die-cutting Size(mm) | 1415×1015 |

| Max. Die-cutting Pressure(T) | 350 |

| Paper Processed(mm) | cardboard 1-9 |

| Max. Die-cutting Speed(s/h) | 4500 |

| Main Motor Power(Kw) | 11 |

| Total Power(Kw) | 17 |

| Weight(Kg) | 16.7 |

| Dimensions(mm) |

6000×4400×2500 3700×2400×2500 |

BMY-1500

| Model | BMY-1500 |

| Die-cutting Style | platen press |

| Max. Paper Size(mm) | 1510×1120 |

| Min. Paper Size(mm) | 550×550 |

| Max. Die-cutting Size(mm) | 1500×1100 |

| Max. Die-cutting Pressure(T) | 350 |

| Paper Processed(mm) | cardboard 1-9 |

| Max. Die-cutting Speed(s/h) | 4500 |

| Main Motor Power(Kw) | 11 |

| Total Power(Kw) | 17 |

| Weight(Kg) | 17.8 |

| Dimensions(mm) |

6300×4500×2500 4000×2500×2500 |

|

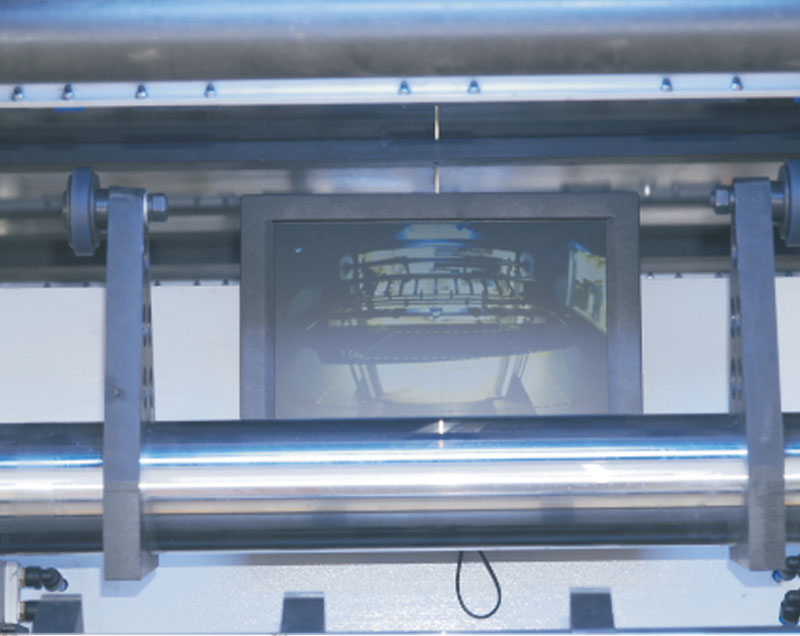

Paper receiving section monitoring display For safety, convenience, the state of paper collection can be found in the working. |

|

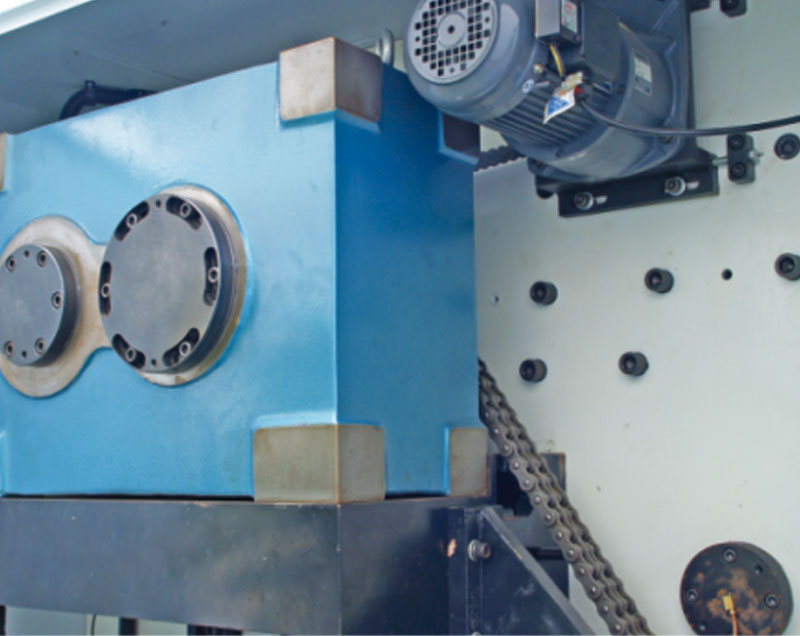

Intermittent mechanism Adopt the unique ternary cam structure, so that the tooth row runs smoothly, ensure the precision die-cutting, improve the service life of the whole machine. |

|

Paper neating device Transverse and longitudinal automatic aligning paper, paper collecting system for waste. |

|

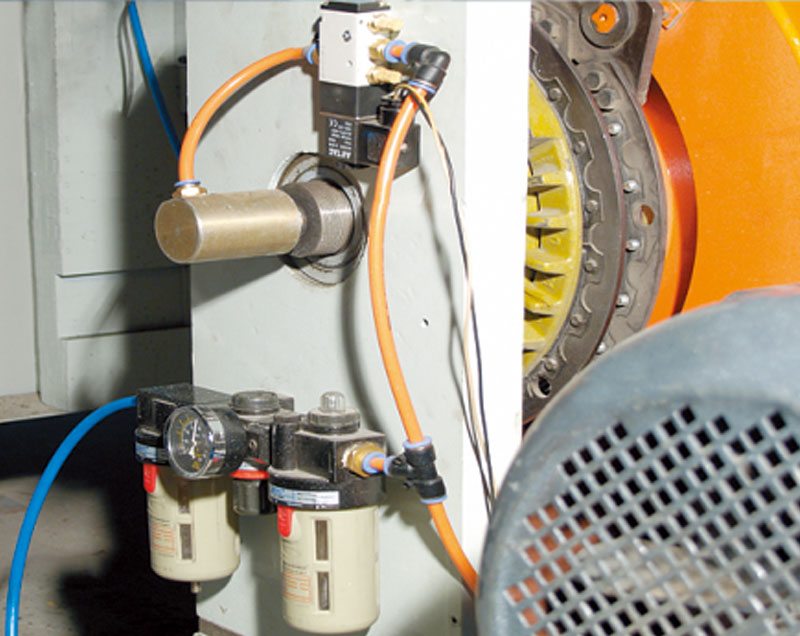

Large torque pneumatic clutch Clutch using large torque pneumatic clutch, fast reaction speed torque is large, and the daily without maintenance, to start, stop, move, accurate action. |

|

Crankshaft Main transmission adopts a worm gear pair and the special design of the crankshaft connecting rod mechanism, the bearing connection, reducing motion space, avoid worm impact, stable operation, die-cutting pressure, and has high pressure maintaining function. Worm gear is made of tin bronze, the life service is long. |

|

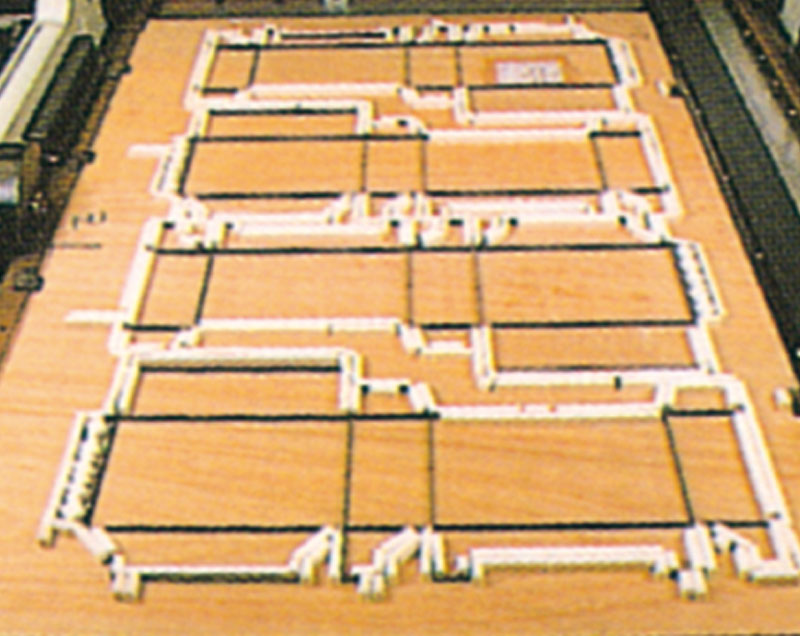

Die-cutting Transmission system with a special design, big pressure, wear resis-tance and long life. Center positioning system and a rotary plate turnover mechanism make the plate change and repair more flexible. The use of wood screw positioning plate, make more flexible plate loading. |

|

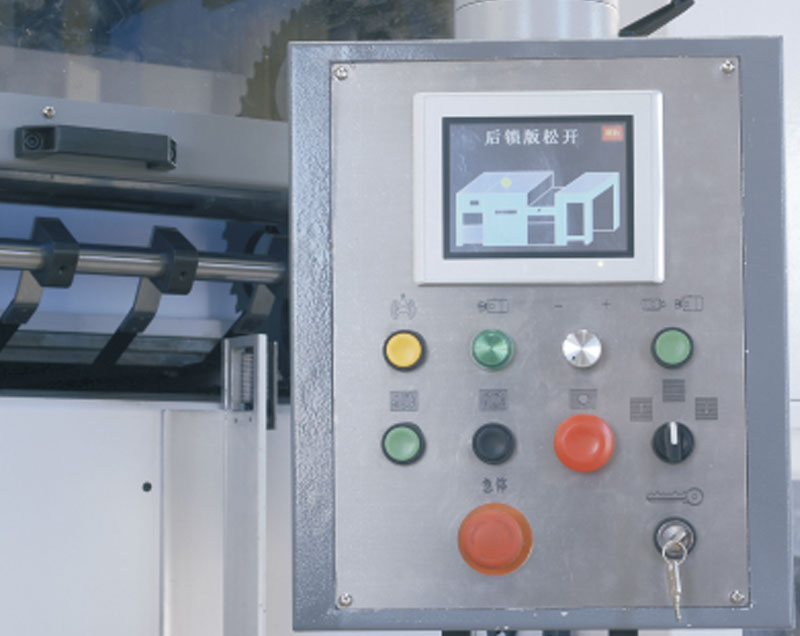

Interface This machine adopts imported touch screen from Japan. All the machine faults can be displayed on the touch screen and all the datas can be adjusted on the touch screen. |

|

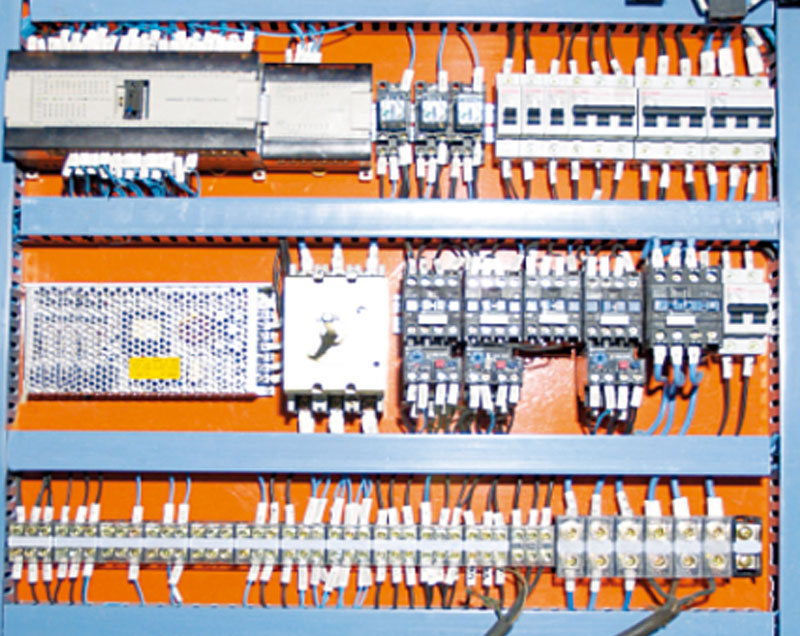

Electronic ministry Electrical control system uses the microcomputer control,achieving automatic control and real-time detection from the paper feeding, paper transferring, paper cutting and paper collecting . |