Die-cutting machine series

FUNCTION CHARACTERISTIC

TECHNICAL SPECIFICATION

LOCAL DESCRIPTION

TECHNICAL FEATURES

1.MY-1050SE adds the function of stripping which can cut off all useless blocks or edges improving the production efficiency.

2.Stripping frame can be lifted automatically easy to operate and reducing time of preparing.

3.Intermittent construction with high precision ensure the stable running of machine.

4.Reasonable construction design solves the problems of low speed and sheet separation

| Max.paper size(mm) | 1050×750 |

| Min.paper size(mm) | 400×360 |

| Max.cutting size (mm) | 1040×720 |

| Feed material (mm) |

80-1200g/m2 cardboard paper, the thickness of corrugated paper ≤4mm |

| Cutting pressure(T) | 300 |

| Min.grabbing-sheet width(mm) | 9 |

| Max.cutting speed(s/h) | 7500 |

| Power required(kw) | 20 |

| Machine length(mm) | 7200 |

| Machine width(mm) | 4000 |

| Machine height(mm) | 2250 |

| Machine weight(T) | 16 |

|

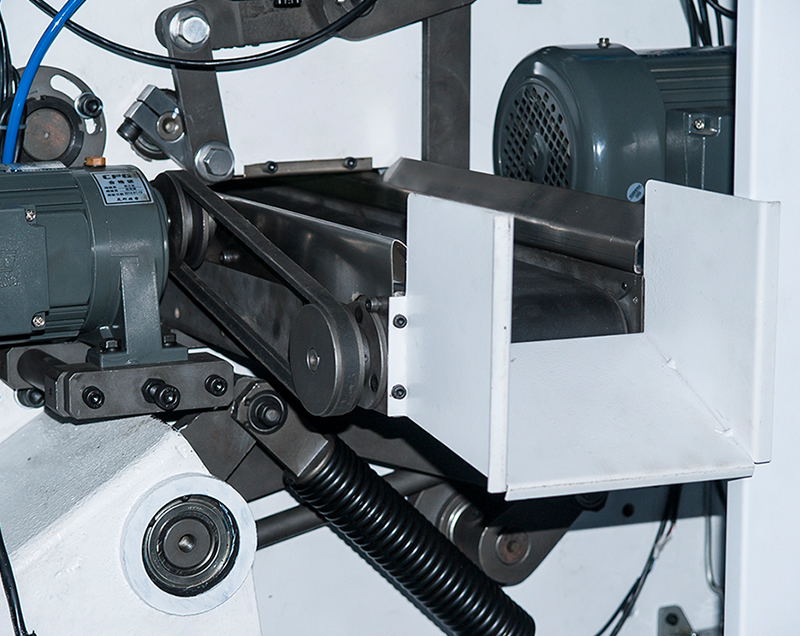

Feeder

1. The feeder with four suckers and four blowers for paperboard and corrugated paper. |

|

Paper Conveying Part 1.Double sheet detector.2.Operating surface and drive surface installed with gauge device. 3.Side gaugefront gauge are equipped with photoelectric detection device. 4.Accumulation paper detection.

|

|

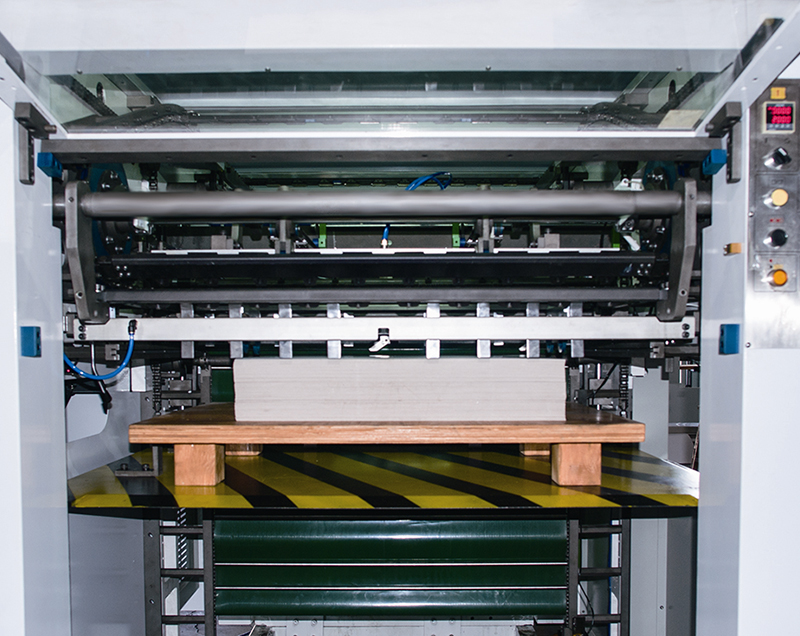

Intermittent mechanism

1.Adopt unique three yuan cam structure so that the tooth row smoothlyensure the precision die-cuttingimprove the service life of the whole machine. |

|

Die-cutting part

1.The die-cutting plate are specially designed for safeeasy to operate. |

|

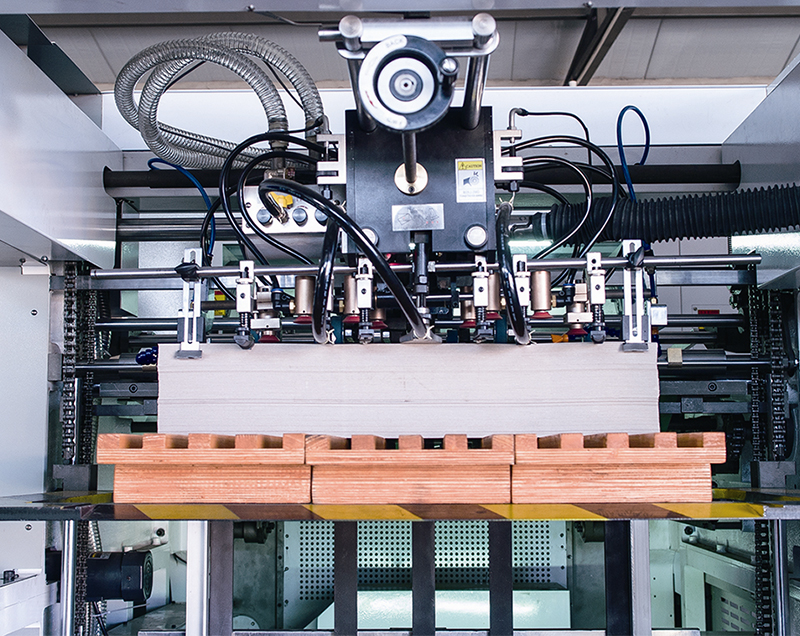

Stripping Station

1.Three frame linkage type stripping deviceaction harmonyprecise and powerful can effectively remove various scrap. |

|

Paper collection

1.Electric vice collection of paper and collection device. |

|

Twice stripping 1.Can clean up the gripper edge easily. |

|

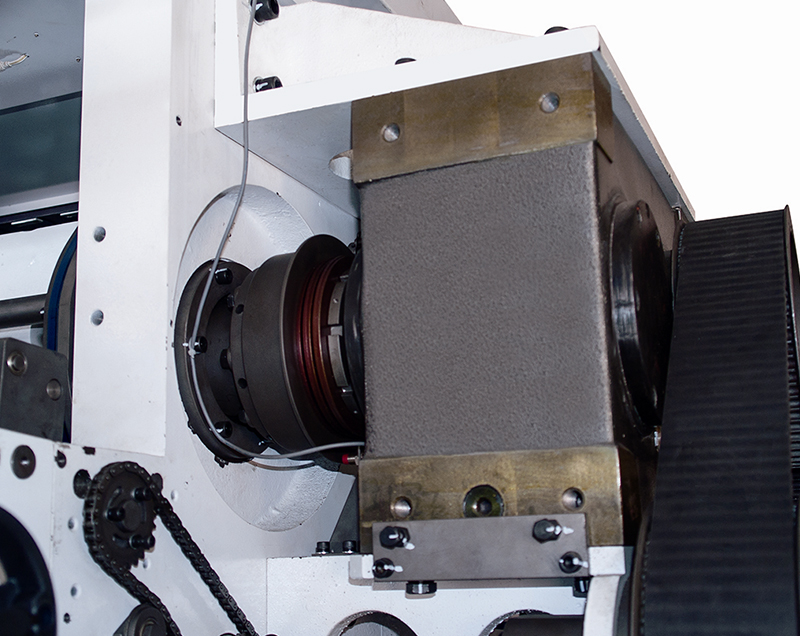

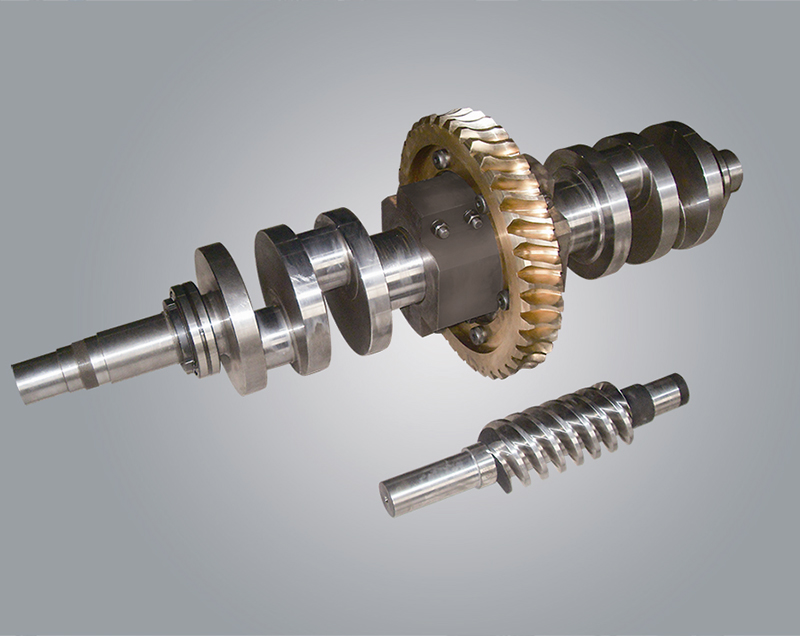

Crankshaft

1.Main transmission adopts a worm gear pair and the special design of the crankshaft connecting rod mechanism. |

|

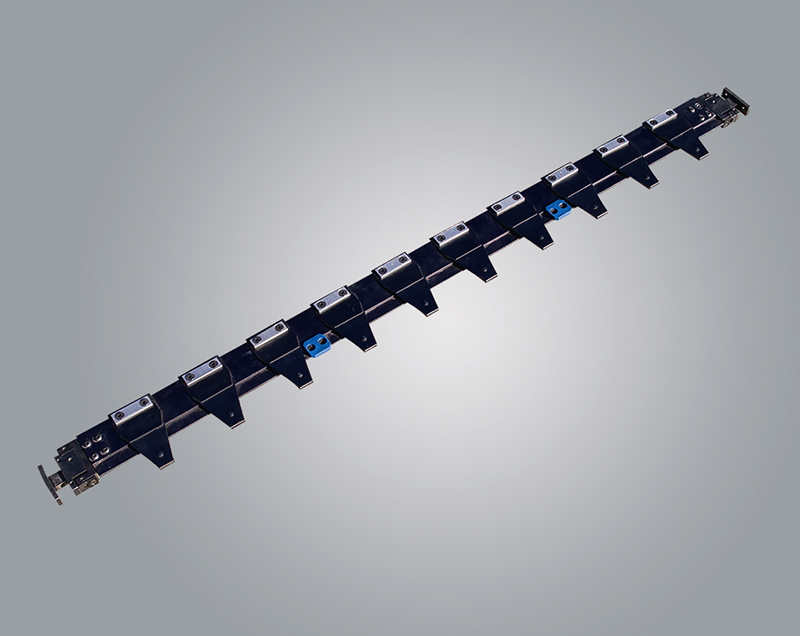

Gripper Bars

1.The gripper bar is made of hard aluminum alloy. |

|

Electronic ministry

1.Electrical control system uses the microcomputer control. |