Window patching machine series

FUNCTION CHARACTERISTIC

TECHNICAL SPECIFICATION

LOCAL DESCRIPTION

STC-1080/1450 automatic window patching machines are special equipment for carton box color box window lamination; They are advanced models in domestic market. Perfect personalization design philosophy ensures that the machines have the feature of high efficiency high-precision high stability and easy operation.

These machines are available for both cardboard and corrugated paper. Adopt non-stop bottom feeder with side lay registration flexible version module of glue print stable and accurate diaphragm incision and cross cutting cropped to achieve tissue boxes gift boxes toy boxes shirt boxes milk cartons and other window film lamination.

These machines are available for both cardboard and corrugated paper. Adopt non-stop bottom feeder with side lay registration flexible version module of glue print stable and accurate diaphragm incision and cross cutting cropped to achieve tissue boxes gift boxes toy boxes shirt boxes milk cartons and other window film lamination.

1080A

| Model | 1080A |

| Max paper size(mm) | 1080×650 |

| Min paper size(mm) | 100×100 |

| Max.film size(mm) | 780×450 |

| Min.film size(mm) | 40×40 |

| Film thickness(mm) | 0.05-0.25 |

| Cardboard(g/㎡) | 200-1000 |

| Corrugate paper(mm) | ≤4.0 |

| Max working speed(s/h) | 10000 |

| Total power(kw) | 10 |

| Overall Dimensions(mm) | 4958x1960x1600 |

| Total weight(T) | 3 |

1080C

| Model | 1080C |

| Max paper size(mm) | 460×650 |

| Min paper size(mm) | 100×100 |

| Max.film size(mm) | 450×450 |

| Min.film size(mm) | 40×40 |

| Film thickness(mm) | 0.05-0.25 |

| Cardboard(g/㎡) | 200-1000 |

| Corrugate paper(mm) | ≤4.0 |

| Max working speed(s/h) | 16000 |

| Total power(kw) | 10 |

| Overall Dimensions(mm) | 4958x1960x1600 |

| Total weight(T) | 3 |

1080G

| Model | 1080G |

| Max paper size(mm) | 1080×1100 |

| Min paper size(mm) | 100×100 |

| Max.film size(mm) | 780×700 |

| Min.film size(mm) | 40×40 |

| Film thickness(mm) | 0.05-0.25 |

| Cardboard(g/㎡) | 200-1000 |

| Corrugate paper(mm) | ≤4.0 |

| Max working speed(s/h) | 16000 |

| Total power(kw) | 10 |

| Overall Dimensions(mm) | 5800x1960x1600 |

| Total weight(T) | 3.5 |

1450A

| Model | 1450A |

| Max paper size(mm) | 1450×1100 |

| Min paper size(mm) | 100×100 |

| Max.film size(mm) | 950×700 |

| Min.film size(mm) | 40×40 |

| Film thickness(mm) | 0.05-0.25 |

| Cardboard(g/㎡) | 200-1000 |

| Corrugate paper(mm) | ≤4.0 |

| Max working speed(s/h) | 10000 |

| Total power(kw) | 12 |

| Overall Dimensions(mm) | 6500x2300x1688 |

| Total weight(T) | 3.8 |

1450B

| Model | 1450B |

| Max paper size(mm) | 680×1100 |

| Min paper size(mm) | 100×100 |

| Max.film size(mm) | 650×700 |

| Min.film size(mm) | 40×40 |

| Film thickness(mm) | 0.05-0.25 |

| Cardboard(g/㎡) | 200-1000 |

| Corrugate paper(mm) | ≤4.0 |

| Max working speed(s/h) | 16000 |

| Total power(kw) | 12 |

| Overall Dimensions(mm) | 6500x2300x1688 |

| Total weight(T) | 3.8 |

|

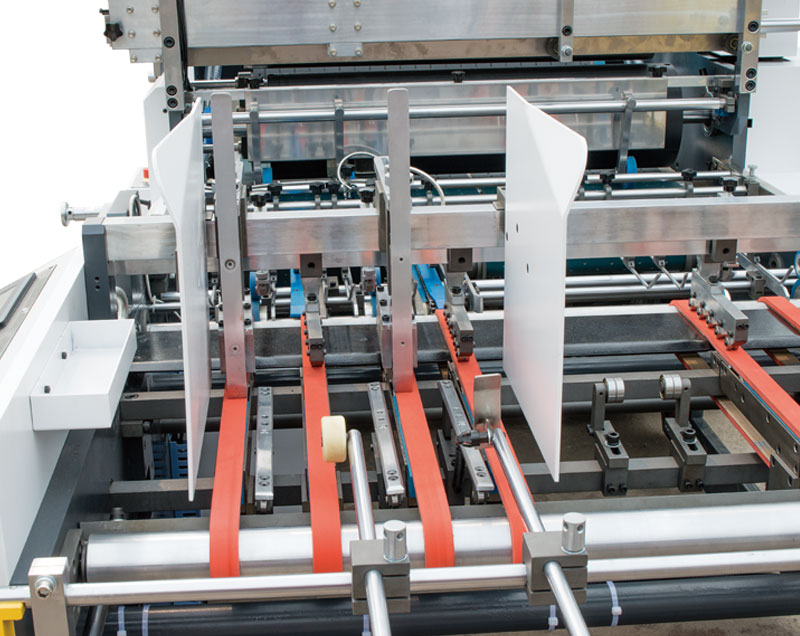

Feeder 1.The feeder is intermittent transportation agency.2. Adopt imported NITTA belt,and imported pneumatic components. 3. Deliver the paper with high speed,stable and reliable. 4. Our company has won the national patent for this part. |

|

Push lay 1. Adopt imported RENOLD chain.2. Deliver the paper with back type push lay. 3. Ensure delivering the minimum paper stably,the minimum paper' s length is 100 mm. 4. Our company has won the national patent for this part. |

|

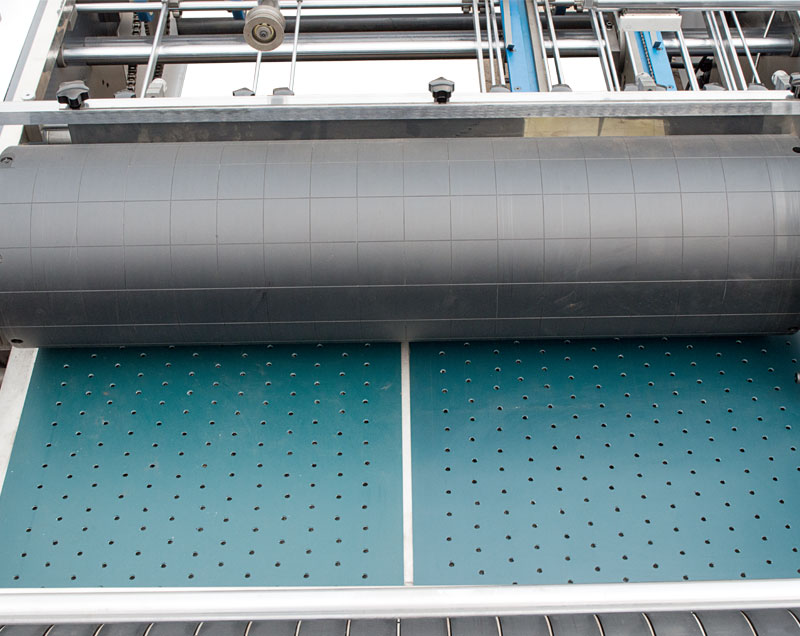

Rotation telescopic rubber roller 1. Single rubber roller cooperate with baffle to gluing. avoid the waste of glue,reduce the volatilization.2. Rotation telescopic rubber roller is perfect personalization design, when the machine stopped,the rubber roller can rotate driving by the motor. 3. Avoid the glue solidify on the face of rubber roller when cleaning the rubber roller, this part can pull-out entirely, reduce cleaning time. 4. Our company has won the national patent for this part. |

|

Gluing 1.Use automatic gluing instead of hand movement, when the photoelectric sensor reacted the paper.2.If there are papers pass,the machine will use the air cylinder to control platform to uplift. If there are no papers pass,the platform will decline to avoid the glue smear on the belt. |

|

Adjustable glue roller 1.This part can adjust the glue roller right and left, up and down.2.Using phase institutions,makes gluing more accurate. 3.The adjustment is faster and more convenient. |

|

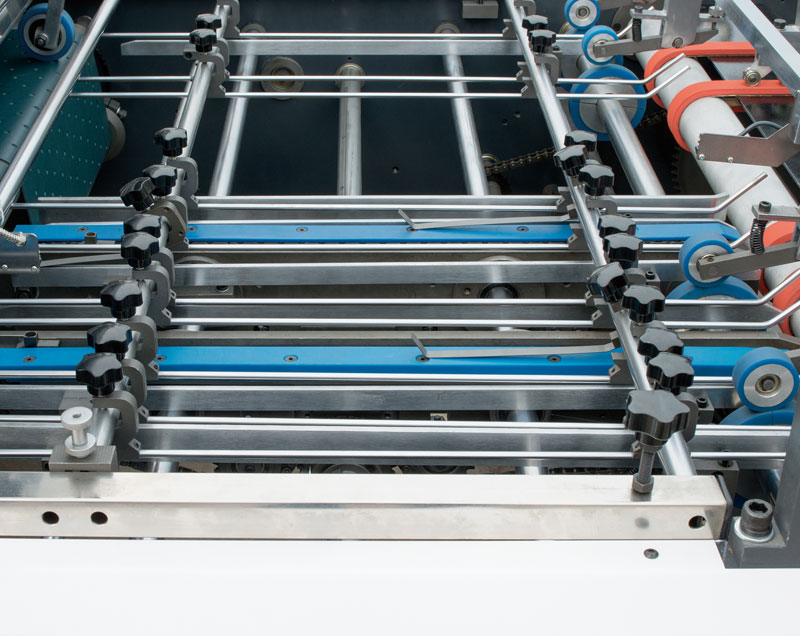

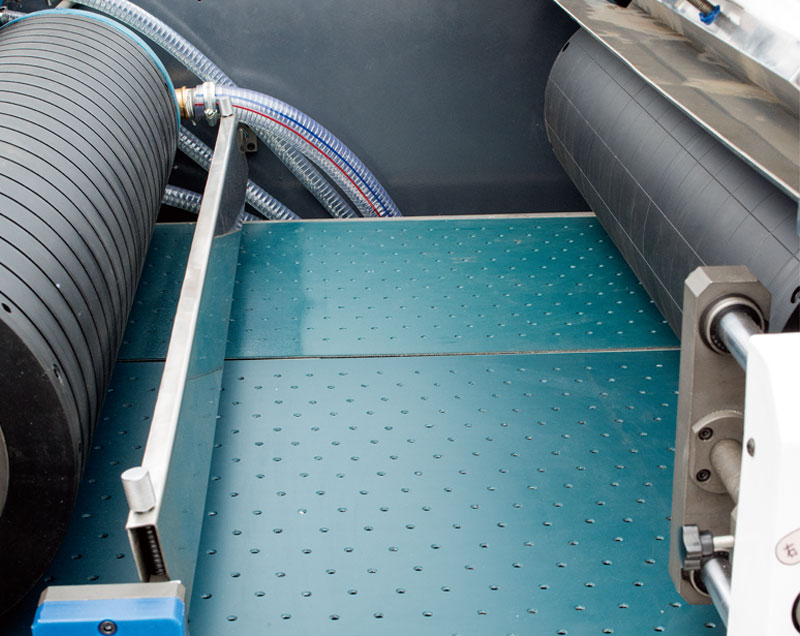

Foreign matter alarm 1. The two suction belts are wide and thick,increase of service life.2. With the device of adjust the wind power, it can adjust wind power according to the sizes of papers, ensure that no position offset. 3.When foreign matter fell out touch the baffle plate, the main motor stop running and alam. 4. Our company has won the national patent for this part. |

|

Film transport 1.Film Transport is controlled by the servo motor.2.With high precision,make the error of cutting the film is less than 0.5mm. 3.Adopt the touch screen to adjust the length of the film,instead of the rotary knob, make the adjustment manner more convenient and efficient. |

|

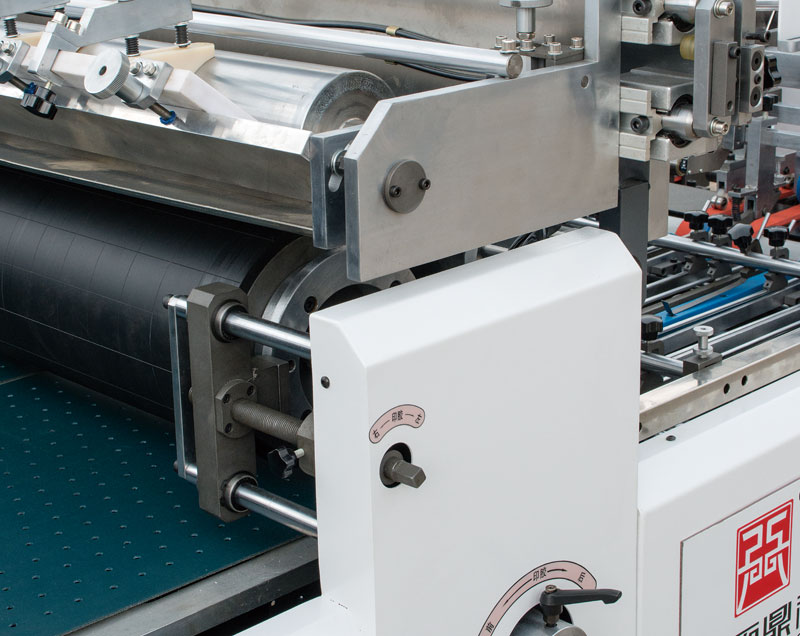

Roller cross knife 1. Quality alloy steel was adopted special heat treatment process manufacturing,to ensure long working hours.2. It instead of the old formula shears cut. 3. Use servo motor adjust the length of the film. so that the machine can runs more accurate, stable and reliable. 4. Adopt unique cutting angle,to cut the thick film more easily. |

|

Jog film cutting (Special for tissue boxes) 1.Special design for the middle cutting of the film, such as tissue boxes point cut, long cut.2.Incision length is adjustable, ensure accurate and never shifting. |

|

Reverse function Gain the reserve function, when installing machine and stopping machine in fixed time, make the operation more easily. |