Paper laminating machine series

FUNCTION CHARACTERISTIC

TECHNICAL SPECIFICATION

LOCAL DESCRIPTION

1. All the key steel parts like steel wall plates camshaft are high grade steel ones and machined in CNC center with high precision to ensure the stability.

2. High speed operation parts like shafts rollers are high grade steel ones and after thermal refining and dynamic balance processing to make the sure the stability when running in high speed in the long run.

3. Motor Conveyors chains bearings and so on are famous brand in domestic and overseas to ensure the stability in the long run.

4. Electric parts are from international brand such as Omron Schneider IDEC and so on.

5. ISO9001 quality system has executed thoroughly. Incoming quality control part testing installation processes inspection whole machine testing are all strictly controlled.

2. High speed operation parts like shafts rollers are high grade steel ones and after thermal refining and dynamic balance processing to make the sure the stability when running in high speed in the long run.

3. Motor Conveyors chains bearings and so on are famous brand in domestic and overseas to ensure the stability in the long run.

4. Electric parts are from international brand such as Omron Schneider IDEC and so on.

5. ISO9001 quality system has executed thoroughly. Incoming quality control part testing installation processes inspection whole machine testing are all strictly controlled.

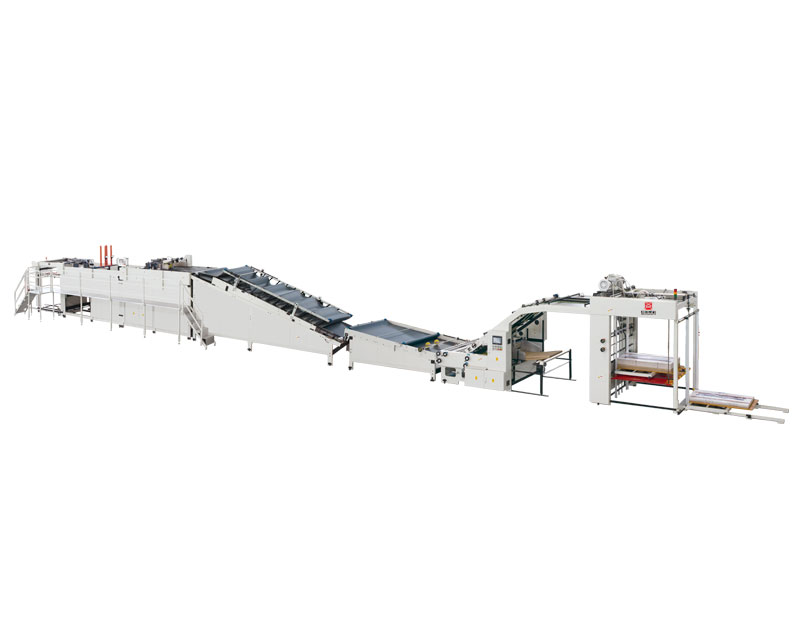

YC146

| Model | YC146 | |

| Max. Sheet Size(mm) | 1450x1450 | |

| Min. Sheet Size(mm) | 500x450 | |

| Thickness of Surface Paper(g/m2) | 180-800 | |

| Appropriate Paper(mm) | A、B、C、D、E、Fcorrugated paper,thickness≤10 | |

| Max. Speed(s/h) |

10000sheets/hour, 160m/min |

|

| Laminating Precision(mm) | ±1.5 | |

| Power(kw) | 27 | |

| Weight(kg) | 15600 | |

| L×W×H (pedal not included)(m) | 28×3.3×2.85 | |

YC166

| Model | YC166 | |

| Max. Sheet Size(mm) | 1650x1650 | |

| Min. Sheet Size(mm) | 500x500 | |

| Thickness of Surface Paper(g/m2) | 180-800 | |

| Appropriate Paper(mm) | A、B、C、D、E、Fcorrugated paper,thickness≤10 | |

| Max. Speed(s/h) |

10000sheets/hour, 160m/min |

|

| Laminating Precision(mm) | ±1.5 | |

| Power(kw) | 27 | |

| Weight(kg) | 17300 | |

| L×W×H (pedal not included)(m) | 30×3.5×3 | |

|

High-efficiency feeder The structure of four lifting suckers and four forwarding suckers is suitable for different type of paper.It also equipped with front-blowing and side-blowing devices in addition to the special pressing-paper foot to blow papers effectively to ensure papers can be transported smoothly. With the pre-loader it can enhance working-efficiency . |

|

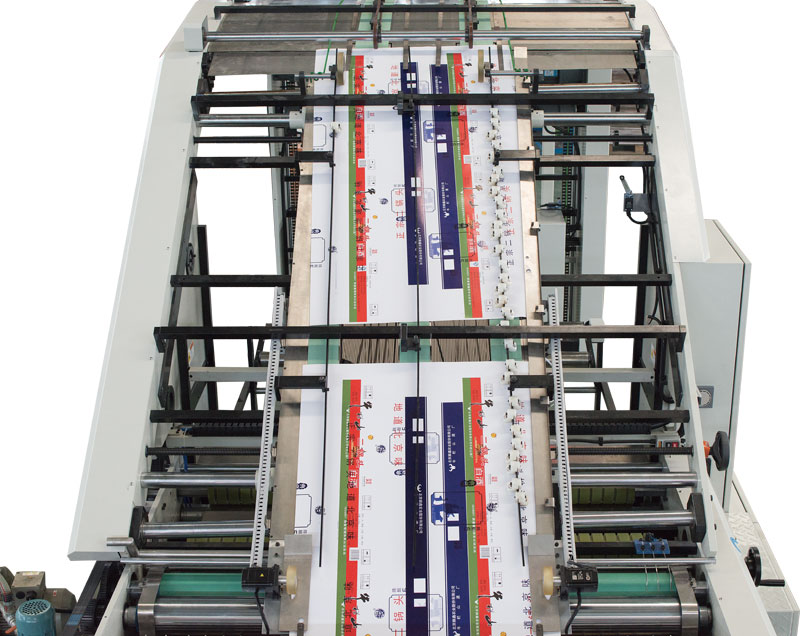

Bottom feeding section With high-efficiency suction belt system the feeding unit for the bottom-paper feeds rapidly and effectively.When feeding corrugated board including single face up to triple wall just adjust suction power for differences in size and board warping. |

|

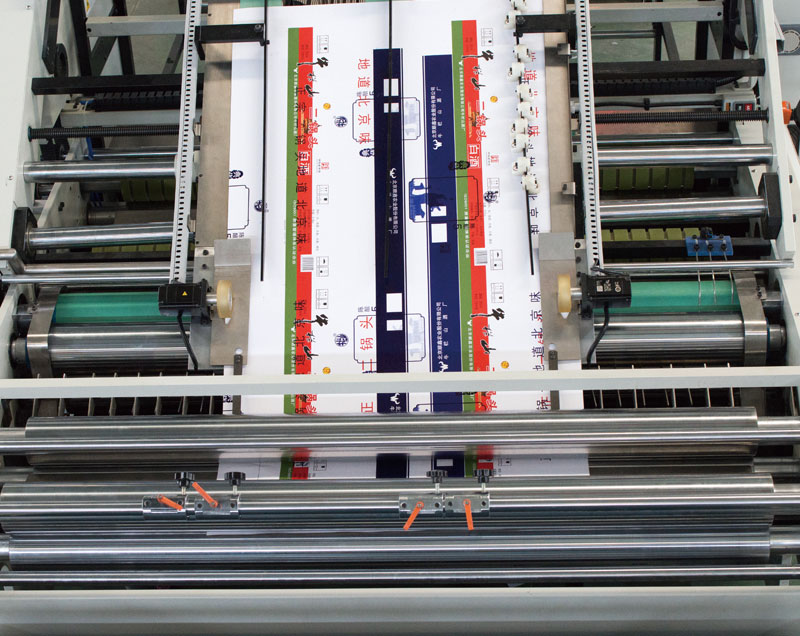

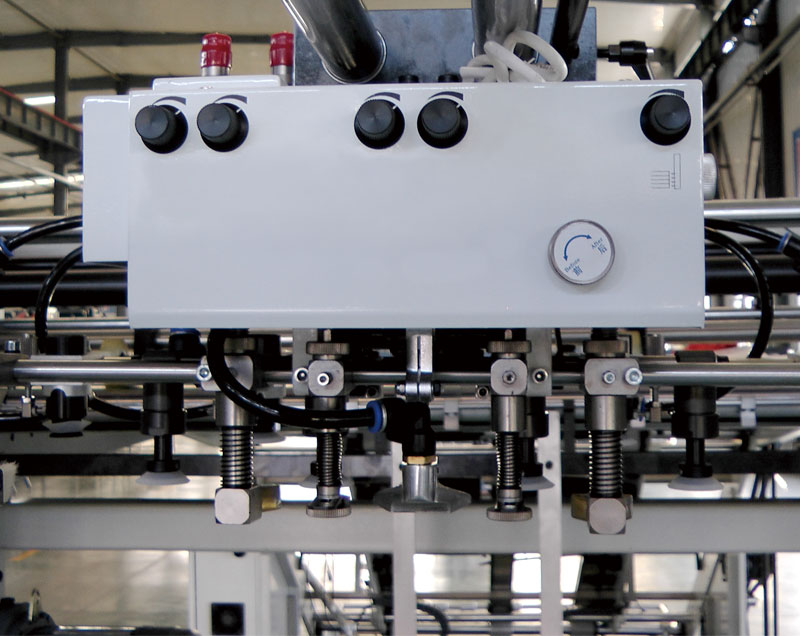

The laminating unit With automatic glue-supply system high-precision glue application roller & metering roller can apply glue on paper evenly and precisely.When laminating the top paper registration will be controlled by two servo motors and the bottom paper controlled by servo motor driven belts in addition to motion controller to ensure precise lamination. |

|

Bundle ejector This section links laminator pressing unit to bundle counter ejector before entering into flip flop section. |

|

Flip flop unit With flip flop function can flip bundles alternatively to offset board warping. |

|

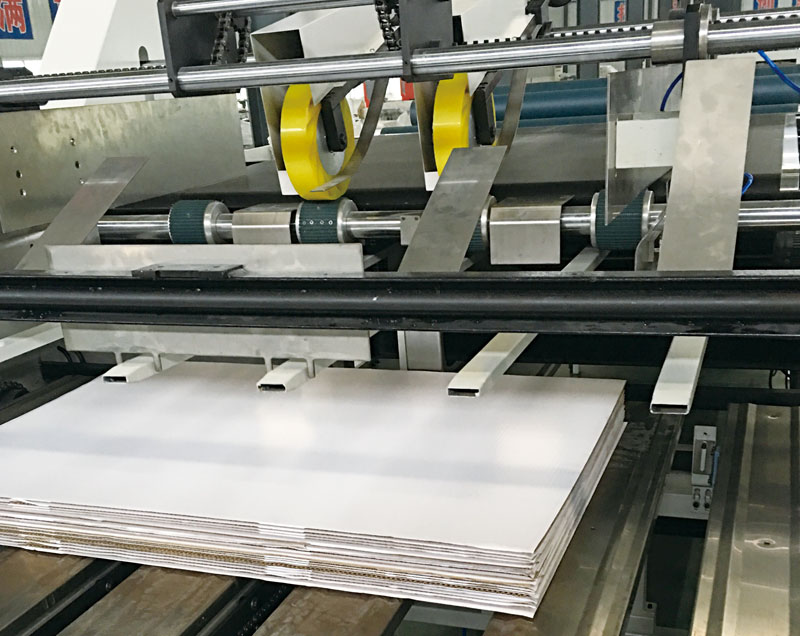

Paper stacking & delivery unit Non-stop automatic stacking of bundles of paper from flip flop unit can stack paper with uniformity.Can be connected with conveyor system for automatic transportation. |